Update on our Bacci 5 axis CNC machine

The arrival of our Bacci 5-axis CNC machine towards the end of last year was a very exciting moment for us and marked a step change in our furniture and wood component making capabilities. So, what’s been happening since our third CNC machine arrived in our Leeds workshop?

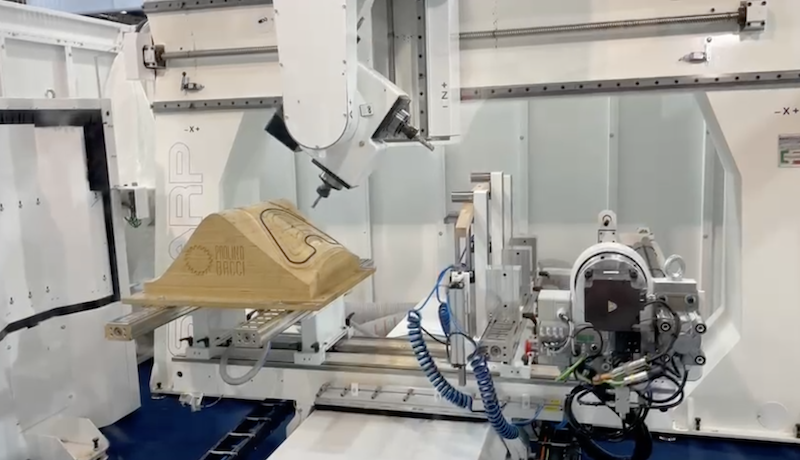

The day our Bacci moved in was quite an event in itself. This is a huge machine and getting it off the truck and into position at the far end of the workshop was no mean feat.

We already had two CNC machines in the workshop, one 3-axis and one 5-axis. This latest 5-axis machine is on another level entirely, boosting our manufacturing prowess on so many levels, not least speed, accuracy and volume.

We’ve all been on a steep learning curve since the Bacci arrived, familiarising ourselves with what it can do and understanding how to programme it to get the most out of it. This is an ongoing process and we are still discovering new ways to improve its accuracy and efficiency.

It has transformed the way we work completely, freeing up our other 5-axis machine to work at full capacity on volume wood components. Meanwhile, we are using the Bacci to refine the manufacturing process of some of our most popular products, such as our wooden trestle legs, as well as making the most of its flexibility and accuracy for special projects and high end components that benefit from that little bit of extra finesse

Dovetailors is one of only a handful of British manufacturers to have this calibre of machine in house, capable of such accuracy and complexity. The cutting tool or component can move along five axes simultaneously, making it ideal for complex shapes and designs. The ease of movement and automated tool changing mechanism still fascinates us, even though we have now watched it many times.

The investment in a third CNC machine makes us highly competitive in the wood component and furniture manufacturing sector. We can compete more effectively with overseas manufacturers on price and volume, opening new avenues for UK manufacturing as a whole and Dovetailors specifically.

We are looking forward to expanding our work with British designers and becoming better known as the wood component manufacturer of choice for furniture brands that are seeking quality, reliability and an agile partnership.

We have been supported in this investment by the Leeds City Region Enterprise Partnership. You can read more here