Third CNC Machine Set to Boost Capacity at Dovetailors

We’re very pleased to announce that we will soon be introducing a third CNC machine to our Leeds workshop to increase our capabilities, expand capacity and make us an even more cost effective option for our existing commercial partners and new clients who are looking for a reliable UK-based supplier.

We’re also looking forward to working with more product developers and emerging designers to provide practical CAD and CNC support and manufacturing expertise as they develop their prototypes with us and test out their designs on small batch runs.

The new 5 axis CNC

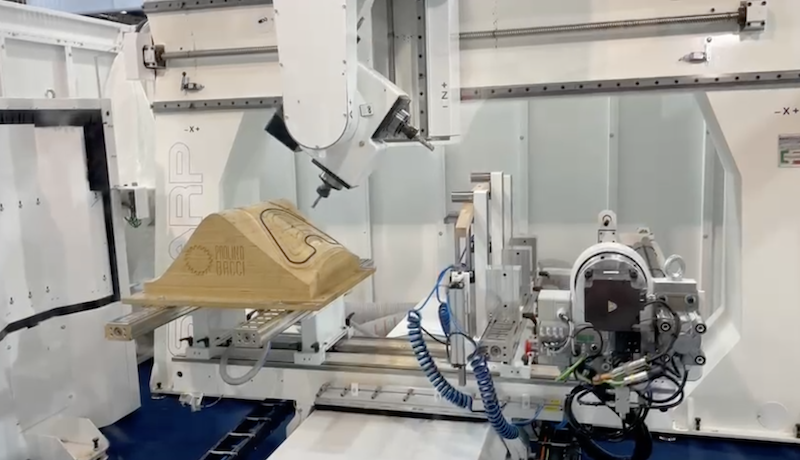

The new machine is an industry leading 5 axis CNC router and lathe by Italian machine maker Bacci. You can see it in action here. We have been supported in this investment by a Leeds City Region Enterprise Partnership.

The Bacci will be our second 5 axis machine. We also have a 3 axis machine in the workshop. The difference with the 5 axis is that the cutting tool or component can move along five axes simultaneously, making it ideal for complex shapes and adventurous designs, much to the delight of the designers in our team who enjoy nothing more than to stretch the boundaries.

From small beginnings

The decision to invest in a third machine has prompted us to reflect on how far we have come as a business since we started out in a small unit in Nidderdale, North Yorkshire, back in 2005.

At that time most of our business was bespoke furniture design for local private customers. Even then, we still had a passion for supporting fellow makers and there was a small gallery section in the workshop where local artists could exhibit.

Major ecclesiastical commissions, including a new altar for Wakefield Cathedral and ceremonial chairs for Sheffield Cathedral, led to job growth and further investment in technology and machinery. We moved to Sunny Bank Mills in Farsley and continued to expand our bespoke furniture and church furniture work. Space was often tight, especially when we were making large commissions such as choir stalls.

In 2019 we moved again to our current site on Stanningley Road in Leeds. Our wood component manufacturing work for high end British furniture companies had really taken off by that time. It’s fantastic to have the extra space and even with the third CNC machine on site we will have plenty of room for storage and manufacturing.

Training future cabinet makers

We have a strong tradition of training cabinet makers. Both our head maker Craig and principal designer Charlotte joined us as trainees. In our current workshop team we have trainee maker Francis and student CNC operator Harley.

There are clear advantages for them in developing their skills and learning in such a busy and varied environment. They pick up so much from our team who can be working on anything from component manufacturing for commercial clients, small batch production for product developers, church furniture projects to bespoke furniture design for private customers.

There are huge benefits for us too as our business gains new talent, ideas and energy – plus an extra pair of hands.

The additional machine will create two new jobs, one in design development and one for a cabinet maker. We will also be taking on a placement student.

Competing on design expertise, skill, versatility and capacity

Investing in a third CNC machine means we can compete with overseas manufacturers more effectively on capacity as well as price which will open more doors and ultimately help us create further skilled design and cabinet making jobs and apprenticeships here in Yorkshire.

Without a doubt, there is a real desire in the commercial world at the moment to use British suppliers wherever possible and we want to make that decision easier.

The new Bacci machine is due to arrive in the workshop this month (October). We’ll be sure to keep you updated. If you would like to talk to us about our CNC services, small batch furniture production, component manufacture or prototyping please get in touch. You can call us on 0113 2567376.